- Product Based Packaging

- Feature Based Packaging

- Style Based Packaging

- Material Based Packaging

Child-resistant packaging is designed to prevent children from accessing regulated products, while still allowing adults to open the package with proper instructions. However, many users struggle with opening child-resistant packaging due to unfamiliar locking mechanisms.

In this guide, we’ll walk you through how to open different types of child-resistant packaging step by step, explain why these packages can feel difficult to open, and answer common questions users have about safety and compliance.

This type of packaging is commonly used for cannabis products, vape devices, edibles, pharmaceuticals, and supplements.

Before we dive into how to open child-resistant packaging, it helps to understand how these packages are designed and produced through a custom cannabis packaging production process that meets both safety compliance and brand requirements.

A typical custom cannabis packaging production process includes:

Concept & Design – This phase defines the package structure (slide-out drawer, tin case, pouch, etc.) and the child-resistant mechanism based on the product type, such as vape, edibles, or pre-rolls.

Material Selection – Choosing materials like rigid paperboard, tinplate, or laminated film that meet durability and regulatory requirements.

Prototype & Testing – Prototypes are created and tested for child-resistant performance and adult usability to ensure compliance with standards such as ASTM or CPSC.

Tooling & Manufacturing – After prototype approval, tooling for die-cutting, embossing, and molds is prepared, followed by full-scale printing and production.

Quality Control – Finished packaging undergoes quality checks, including mechanism integrity, print quality, and child-resistant performance before shipment.

Compliance Documentation – Certifications and documentation are provided to support sales in regulated cannabis markets.

Understanding this process explains why child-resistant packaging can feel complex to open — it is engineered with multiple safety layers from production to meet legal and consumer safety standards.

Child-resistant packaging often requires two simultaneous actions, such as pressing and turning or squeezing and sliding. These mechanisms are intentionally designed to challenge children’s motor skills and strength.

For adult users, difficulty opening the package is usually due to unfamiliarity with the mechanism rather than a defect in the packaging.

In many regions, child-resistant packaging is legally required for cannabis, vape products, and certain edibles. Regulations may vary by state or country, but compliance standards often reference testing protocols such as CPSC or ASTM guidelines.

Always consult local regulations to confirm specific requirements for your product category.

For a more structured comparison of the popular child-resistant packaging structures used in the cannabis industry — from rigid boxes to tins and bags — explore our expert guide.

Paper-based child resistant (CR) button mechanisms are commonly used in a variety of rigid and semi-rigid paper box structures, including:

• Sliding cardboard boxes

• Folding paper boxes

• Setup-style rigid paper boxes

These formats balance safety, functionality, and premium presentation, making them especially popular in regulated markets.

Paper CR button boxes are widely used across cannabis product categories, including:

• Vape devices – From standard 510 cartridges to various pod-style vape cartridges

• Pre-roll joints – Single or multi-pack configurations in different capacities

• Edibles – Such as chocolate bars, gummies, and other infused food products

Step 1: Locate the marked push area on the box.

Step 2: Apply pressure to the marked area using your thumb.

Step 3: While pressing, slide the inner tray out in the indicated direction.

Tip: Do not pull the tray without pressing the locking area, as this may damage the box.

Child resistant (CR) tin cases are widely used in the cannabis industry due to their durability, strong locking performance, and excellent sealing properties.

They are especially popular for pre-roll joints and gummy edibles, where protection and freshness are critical.

Common CR tin case formats include:

• Sliding tin cases

• Flip-top child resistant tin cases

• Squeeze-and-turn round tin cases (widely used for gummies)

Each structure offers a different balance of usability, security, and visual appeal.

Front-Button Style

Press both front buttons at once, then lift or slide the lid open. (Ideal for pre-roll joints)

Side-Tab Style

Press or squeeze both side tabs inward, then push or slide the lid open. (Ideal for pre-roll joints)

Press the cap down firmly, rotate counterclockwise while pressing, then release to open. (Ideal for gummies)

From a packaging design perspective, CR tin cases are widely used because:

Strong mechanical resistance, making them difficult for children to open

Durable and reusable, ideal for repeated consumer use

Child resistant certified, compliant with regulatory requirements

Excellent sealing performance

Cost-effective for large-volume production

For pre-roll joints, tin cases help retain moisture and prevent damage.

For gummies, the tight seal helps maintain freshness and prevent odor leakage.

Selecting the correct Child resistant tin size is the first step in customizing your pre-roll or gummy tin case. Proper sizing ensures product protection, user convenience, and efficient packaging

Glass Dab jars

Glass flower containers

The lid uses a ratchet-style locking system.

The lock disengages only when downward pressure is applied while rotating the lid.

Step 1: Place your palm on the lid.

Step 2: Press down firmly.

Step 3: While pressing, turn the lid counterclockwise to open.

If the lid does not turn, ensure you are applying enough downward pressure before rotating.

Typical packaging types

Cannabis mylar bags

Flexible pouches for edibles or flower

The zipper includes a child resistant locking track.

The bag opens only when pressure is applied at a specific release point.

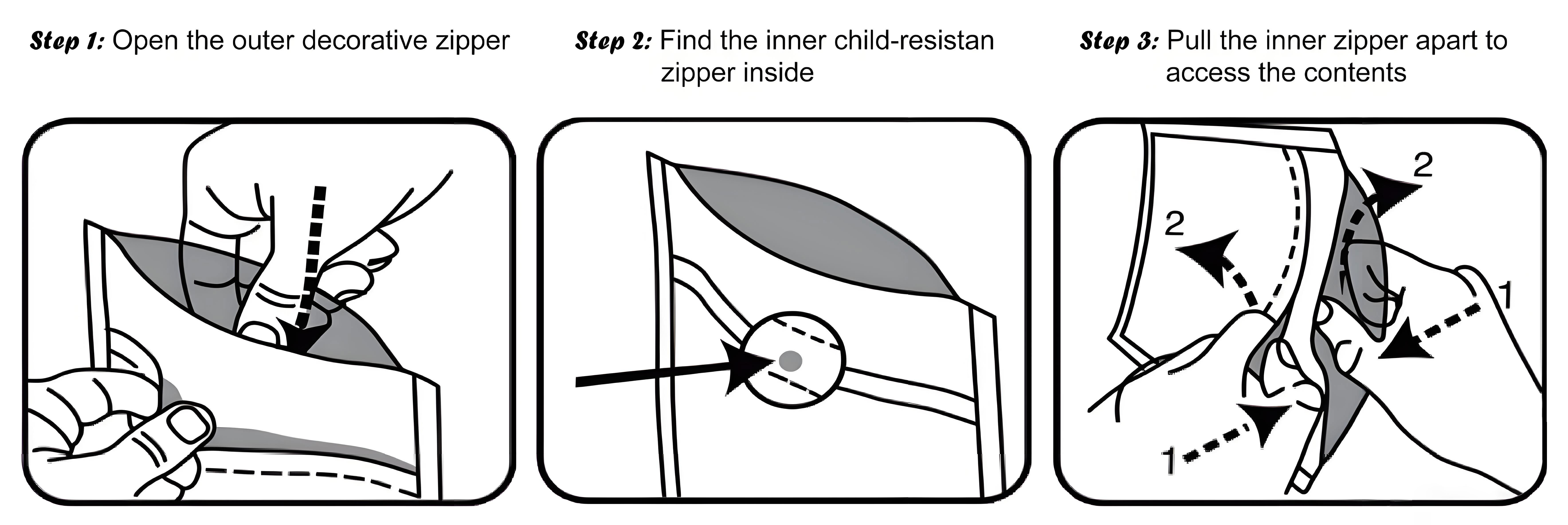

Step 1Child-resistant mylar bags often feature a hidden or false zipper design.

Step 2: Identify the tear notch or opening indicator.

Step 3: Tear along the notch to access the hidden zipper.

Step 4: Pull the inner zipper apart to open the bag.

The outer zipper is decorative and does not open the bag.

• The package won’t open even after following the steps

→ Try increasing pressure while performing the opening action.

• The packaging feels defective

→ Most child-resistant mechanisms require precise alignment rather than force.

• Seniors find it difficult to open

→ Some CR designs offer senior-friendly options while remaining compliant.

Q: Is child-resistant packaging child-proof?

A: No. Child-resistant packaging is designed to reduce risk, not eliminate it entirely.

Q: Why do adults sometimes struggle to open CR packaging?

A: Most issues are caused by unfamiliarity with the locking mechanism.

Q: Can child-resistant packaging be reused?

A: Some designs allow limited reuse, but effectiveness may decrease over time.

Q: Is child-resistant packaging required for vape and cannabis products?

A: In many jurisdictions, yes, especially for products accessible to consumers.

Explore more about child resistant boxes and Dispensary Packaging Solutions on our site to find the perfect fit for your cannabis products.

We provide a wide range of child resistant cannabis packaging, including:

Child resistant cardboard boxes

Child resistant vape packaging

Child resistant tin cases

Child resistant mylar bags

All packaging is designed for marijuana and CBD compliance in the US market.

Simply contact us with the following details:

Product type & size

Target market

Estimated quantity

Customization requirements

Our team will provide a tailored packaging recommendation and quotation.

Choosing the right CR packaging depends on:

Product type (vape, edible, flower, concentrate)

Target market & regulatory environment

Brand positioning & budget

Retail display requirements

Our team will recommend the most suitable solution based on your specific needs.

Typical lead times are:

Sampling: 7–15 days (depending on structure)

Mass production: 20–35 days

Timelines may vary based on order quantity, customization, and materials.

Yes.

While regulations vary by state, we support compliance-focused packaging design by:

Recommending suitable CR structures

Aligning packaging with market requirements

Supporting sampling, testi选择分类

ng, and QC processes

Our experience serving North American cannabis brands helps reduce compliance risks.

Depending on the packaging type, materials may include:

Rigid paperboard or folding carton

Tinplate metal

Plastic (PP / PET)

Glass containers

Multi-layer laminated films (for mylar bags)

Material selection is based on product protection, compliance, and brand positioning.

Yes.

We offer full customization including:

Packaging structure & CR mechanism

Size & capacity

Material & finish

Printing, colors, and branding

Our in-house design and engineering team supports custom development from concept to production.

MOQ varies depending on packaging type, structure, and customization level.

Paper CR boxes: typically lower MOQ

Tin cases & jars: structure-dependent

Mylar bags: flexible MOQ options available

Please contact our team with your product details for an accurate quotation.

Our child resistant packaging structures are engineered to meet recognized child resistant standards and are widely adopted by cannabis brands in regulated markets.

Certification requirements may vary depending on structure and application. We support compliance-oriented design and can guide clients during structure selection and development.

We provide a full range of certified child resistant packaging solutions, including:

Child resistant paperboard boxes (sliding, drawer, flip-top)

Child resistant tin cases (push-and-slide mechanisms)

Child resistant mylar zipper bags

Child resistant jars & containers (glass or plastic)

All solutions are designed for regulated cannabis markets and support custom branding.