- Product Based Packaging

- Feature Based Packaging

- Style Based Packaging

- Material Based Packaging

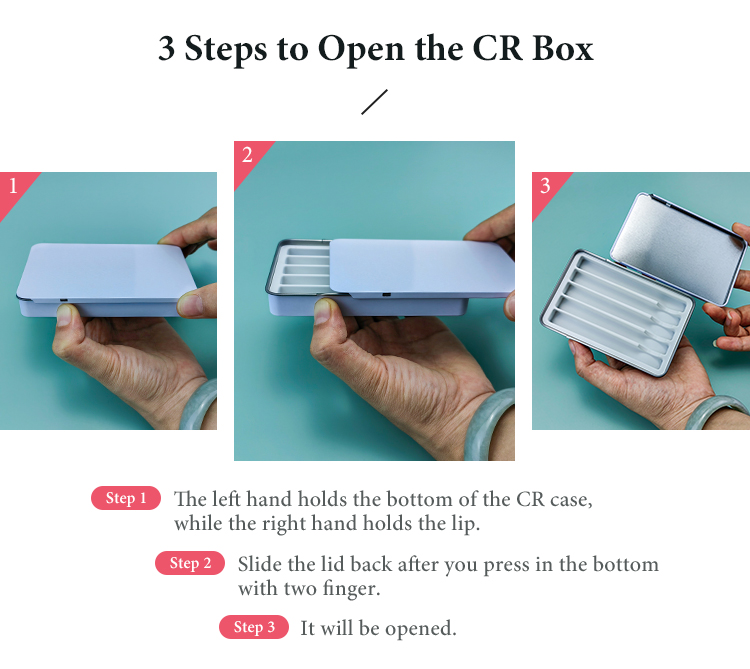

- Child-resistant sliding metal tin container for pre roll packaging

- Can be customized with an embossed logo, design, or printing

- Can be adapted to fit different pre-roll sizes (blunt, king-size, mini joints)

- PVC and paperboard inserts,

- Can be customized for multi-pack options( basically ranging from 3 - 10 Pack)

- Optional match slot can be added to the insert for easier use

- Support customization for personalized branding and designs

| Availability: | |

|---|---|

CR007

YARK

001

Cannabis pre-roll demand has been steadily increasing in recent years. Pre-roll joints offer a similar experience to traditional cigarettes, making them a popular choice for consumers.

One of the advantages of pre-roll joints is the availability of various capacity options, including Mini pre-roll, 3/4 medium to full king-size.

In response to the changing market dynamics, Yark, a leading provider of cannabis packaging solutions, has introduced suitable pre-roll packaging.

Custom cardboard packaging remains a popular option for pre-roll packaging, but more and more cannabis manufacturers are opting for child-resistant (CR) tin containers.

There are several reasons why CR tin cases are becoming increasingly popular:

1. Higher Sealing Requirements: Unlike cardboard packaging, CR tin cases provide a superior sealing option. This makes them an ideal choice for cannabis pre-roll manufacturers who are concerned about maintaining freshness and preventing leaks.

2. Food Grade Material: The raw material used in CR tin cases is metal, which is a food-grade packaging material. This not only ensures the safety of the contents but also enhances the overall appeal of the packaging.

3. Furthermore, metals are a recyclable and environmentally friendly material, which benefits cannabis manufacturers who pursue an environmentally friendly approach.

This is particularly advantageous for pre-rolled joints, as metal can be recycled and reused multiple times, reducing waste and conserving natural resources.

4. One of the most significant advantages of using CR tin cases for pre-rolled joints is the customization option. These cases can be customized according to the specific needs of customers, making them highly attractive to brand owners.

This customization allows brand owners to create a unique and visually appealing packaging for their pre-rolled joints, which can enhance their overall brand image and appeal to customers.

5. In terms of customization, CR tin cases can be adapted to different sizes of pre-roll joints. For mini-pre-roll joints, the 117 x 70 x 16mm CR tin case can be flexibly customized, allowing for various insert options to accommodate the smaller joints. This flexibility allows manufacturers to create a range of multi-pack options, with 5-10 packs being common for mini-pre-roll joints.

For medium to king-size pre-roll joints, the 3-7 packs are common. This adaptability ensures that manufacturers can cater to different preferences and sizes of pre-rolled joints, providing customers with a wide range of choices.

To get started with your custom preroll packaging project, contact us today

We provide a wide range of child resistant cannabis packaging, including:

Child resistant cardboard boxes

Child resistant vape packaging

Child resistant tin cases

Child resistant mylar bags

All packaging is designed for marijuana and CBD compliance in the US market.

Simply contact us with the following details:

Product type & size

Target market

Estimated quantity

Customization requirements

Our team will provide a tailored packaging recommendation and quotation.

Choosing the right CR packaging depends on:

Product type (vape, edible, flower, concentrate)

Target market & regulatory environment

Brand positioning & budget

Retail display requirements

Our team will recommend the most suitable solution based on your specific needs.

Typical lead times are:

Sampling: 7–15 days (depending on structure)

Mass production: 20–35 days

Timelines may vary based on order quantity, customization, and materials.

Yes.

While regulations vary by state, we support compliance-focused packaging design by:

Recommending suitable CR structures

Aligning packaging with market requirements

Supporting sampling, testi选择分类

ng, and QC processes

Our experience serving North American cannabis brands helps reduce compliance risks.

Depending on the packaging type, materials may include:

Rigid paperboard or folding carton

Tinplate metal

Plastic (PP / PET)

Glass containers

Multi-layer laminated films (for mylar bags)

Material selection is based on product protection, compliance, and brand positioning.

Yes.

We offer full customization including:

Packaging structure & CR mechanism

Size & capacity

Material & finish

Printing, colors, and branding

Our in-house design and engineering team supports custom development from concept to production.

MOQ varies depending on packaging type, structure, and customization level.

Paper CR boxes: typically lower MOQ

Tin cases & jars: structure-dependent

Mylar bags: flexible MOQ options available

Please contact our team with your product details for an accurate quotation.

Our child resistant packaging structures are engineered to meet recognized child resistant standards and are widely adopted by cannabis brands in regulated markets.

Certification requirements may vary depending on structure and application. We support compliance-oriented design and can guide clients during structure selection and development.

We provide a full range of certified child resistant packaging solutions, including:

Child resistant paperboard boxes (sliding, drawer, flip-top)

Child resistant tin cases (push-and-slide mechanisms)

Child resistant mylar zipper bags

Child resistant jars & containers (glass or plastic)

All solutions are designed for regulated cannabis markets and support custom branding.